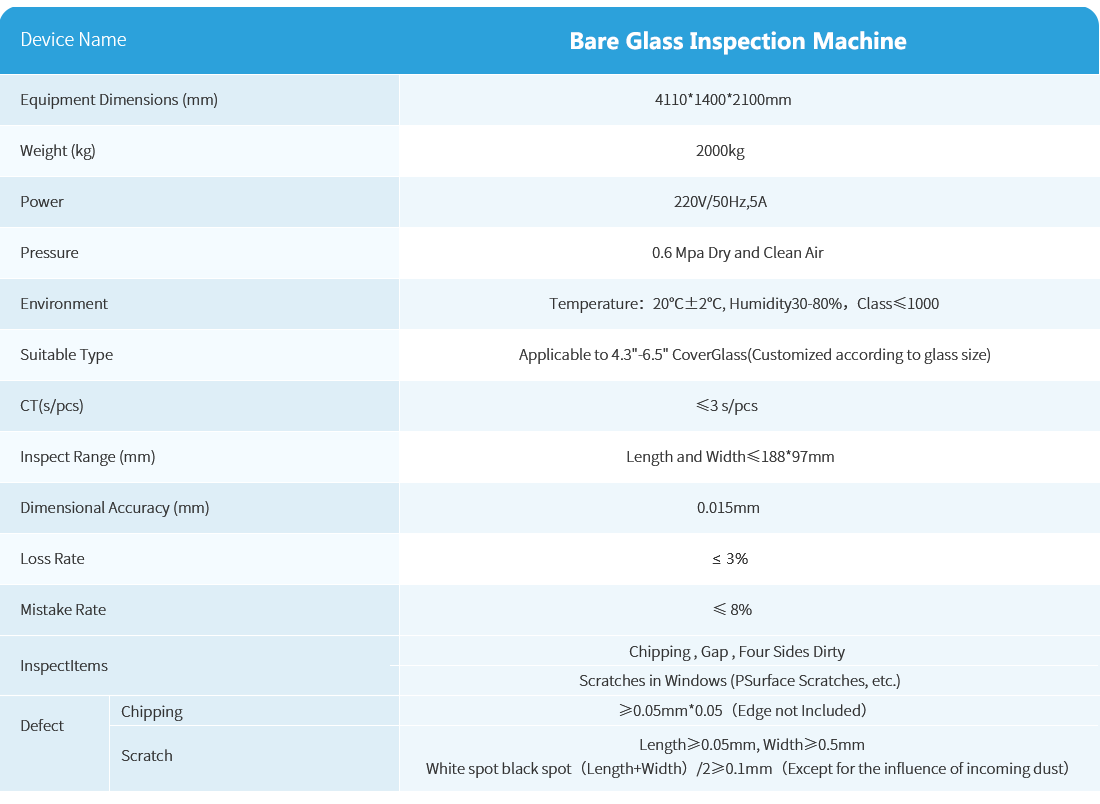

The high precision positioning platform independently developed by our company, with high-speed translation module, multi-station synchronous operation, ensures fast and stable detection effect.

Software automatically detects scratches, edges and dirty functions on blank glass.