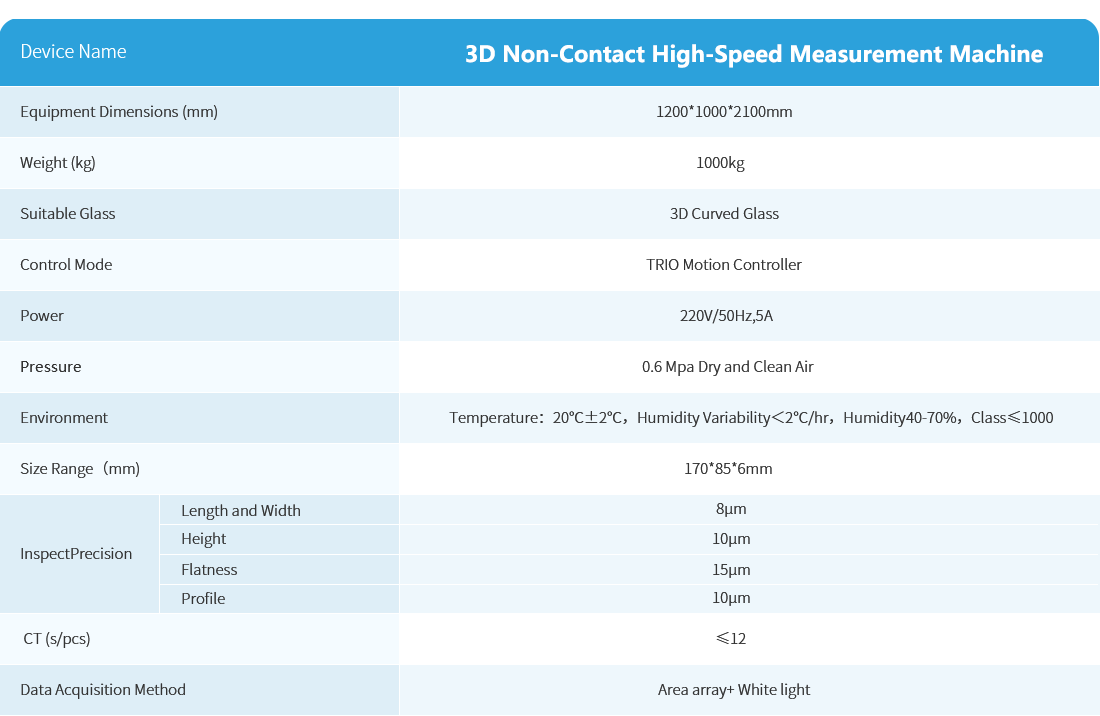

Once 3D products are put into mass production after the process is stabilized, the product size can be controlled through key dimensions such as length, width, height, flatness, hole size and line profile. Boson 3D Non- Contact High-speed Inspect Machine uses machine vision 2D technology, 3D technology and automatic control technology to make rapid measurement of key dimensions of 3D products. The inspection machine uses 2D high-resolution industrial camera to shoot the projected image of the product and obtain key dimensions such as length, width, outer contour and hole position size. Boson 3D Non-Contact High-Speed Measure Machine use line confocal technology to carry out all-size measurement of the profile, R corner and flatness of 3D curved cover glass. The machine can quickly scan product and generate inspection report automatically, so as to facilitate engineering analysis. With our Cover Glass Load & Unload Smart Robot, it can achieve automatic production and inspection.